Most of us started our first 3D print with a sample that the manufacturer of our printer included in the box. This is most likely PLA filament.

PLA is the most commonly used material in hobby 3D printing but also in prototyping and other professional applications because it is fairly easy to print.

Some History

PLA stands for Polylactic Acid. It was discovered in 1932 and it is a compostable and bio-based polyester. PLA is made from fermented plant starch such as from corn, sugarcane or sugar beet pulp.

PLA was first used in the biomedical field because PLA can be fully absorbed biologically. It takes between 6 months and 2 years to fully break down inside the body.

We are probably not going to conduct any medical experiments any time soon so let’s look at the advantages of PLA as far as 3D printing goes.

Advantages of PLA

- Easy to use. PLA is easy to print due to it’s ability to adhere good to your build plate even when the plate is not heated. Also nice that i6t does not give off any toxic fumes or foul odors.

- Low temperature printing. PLA has a low melting point (pure PLA will melt between 150 and 160 C) with 3D print filament usually starting from 180C up. Because of the relatively low melting temperature the chance of your prints warping or your print nozzle getting clogged.

- Easy to post-process. PLA can be easily sanded, painted or polished. Even just removing a slight imperfection is not too hard. You can mechanically reshape your 3D print if needed by drilling, milling etc. Just be aware that the temperature needs to be kept low so slow and plenty of lubricant is the advice.

- Many colors and special blends available. PLA is available in many colors. They range from soft tan to bright orange. PLA is also available as a luminescent variant or with mixed in glitter or wood.

More tech savvy individuals will like the availability of carbon or metal enforced PLA. A word of caution here that your print nozzle (most likely brass) will wear out faster with these blended PLA filaments. - Biodegradable material. PLA is considered an eco-friendly material. It is biodegradable, even when the blended materials reduce this somewhat. It requires less energy to produce and print that petrochemical equivalent plastics (ABS).

All these sound great but there are, as always, less desirable qualities of PLA.

Disadvantages of PLA

- Mechanical strength. PLA is typically weaker and has lower tensile strength than plastics like ABS or PETG. PLA is a fairly brittle material which limits its mechanical abilities and application.

- Heat resistance. PLA has a low melting temperature which is great for printing but not so good for that cup holder in your car on a sunny summer day. PLA can easily deform under stress when temperatures are elevated.

- Oozing and stringing. PLA has a bit of oozing and stringing issue due to the low melting temprature. This can be effectively countered by adjusting retraction settings and cooling.

- Food safety. PLA as a material is in general considered food safe. However, the 3D print process creates surfaces that can be absorbent and rough. This is a perfect environment for mold and bacteria to build up. Please do not use 3D printed PLA containers for food or drink.

Finally, some quick and generic tips on printing and handeling PLA.

Tips for printing and handeling PLA

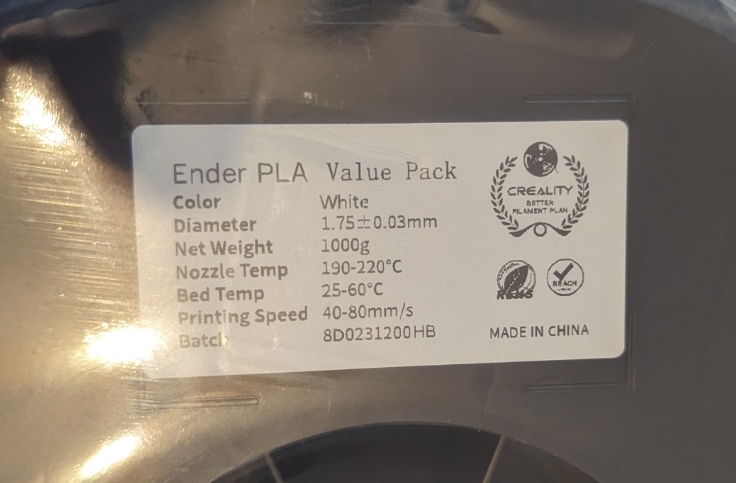

- Nozzle temperature: read the filament manufacturers recommended temperatures! As you can see in the image: the recommended nozzle temperature for this PLA is 190-220C. I usually start at the average of the two and that is in this case 205C. (eg. (190+220)/2 )

- Build plate temperature. Also called bed temperature. We have it listed on the label as 25 – 60C. So, this means we can use a ‘cold’ bed or heated and controlled up to 60C. It is not recommended to go above the 60C as the pla becomes soft and weak very fast.

- Printing speed. Here is an item of intense discussion that may take many hours of research, trials and theories. The manufacturer recommends a speed range but does not know which 3D printer you have nor its capabilities. I have printed this material at 180 mm/s without issues related to the filament. The print speed limitation from the filaments point of view is only its capability to melt and be extruded fast enough to keep up with the deposition speed. When in doubt, start on the slower side and work your way up.

- Cooling. The cooling during printing is an essential component to ensure accuracy and details in your prints. PLA usually get the maximum cooling you can deliver except for the first couple of layers where no or very little cooling helps you print adhere well to the build plate.

- Handeling and storage. PLA does not print very well when it is moist. PLA is by no means as bad as PETG or worse Nylon as far as absorbing moisture but if you live in a high humidity climate it is advisable to store your PLA in airtight packaging or containers with a desiccant. Your PLA will feel brittle and bubble during printing when it contains too much moisture. There are several filament dryers on the market ranging in print from about US$40 and up if you need one. You cannot dry filament with a desiccant!

Make sure that you always keep a hand on the loose end of the filament when inserting or removing it from your printer. Thread in through the holes that most spools have near the edge to hold the end secure. When it gets loose it is easy to slip under another winding on the spool and get tangled. You will most likely not find out until you are in the middle of your next print and strange mechanical noises come from your printer or worse.

Leave a Reply